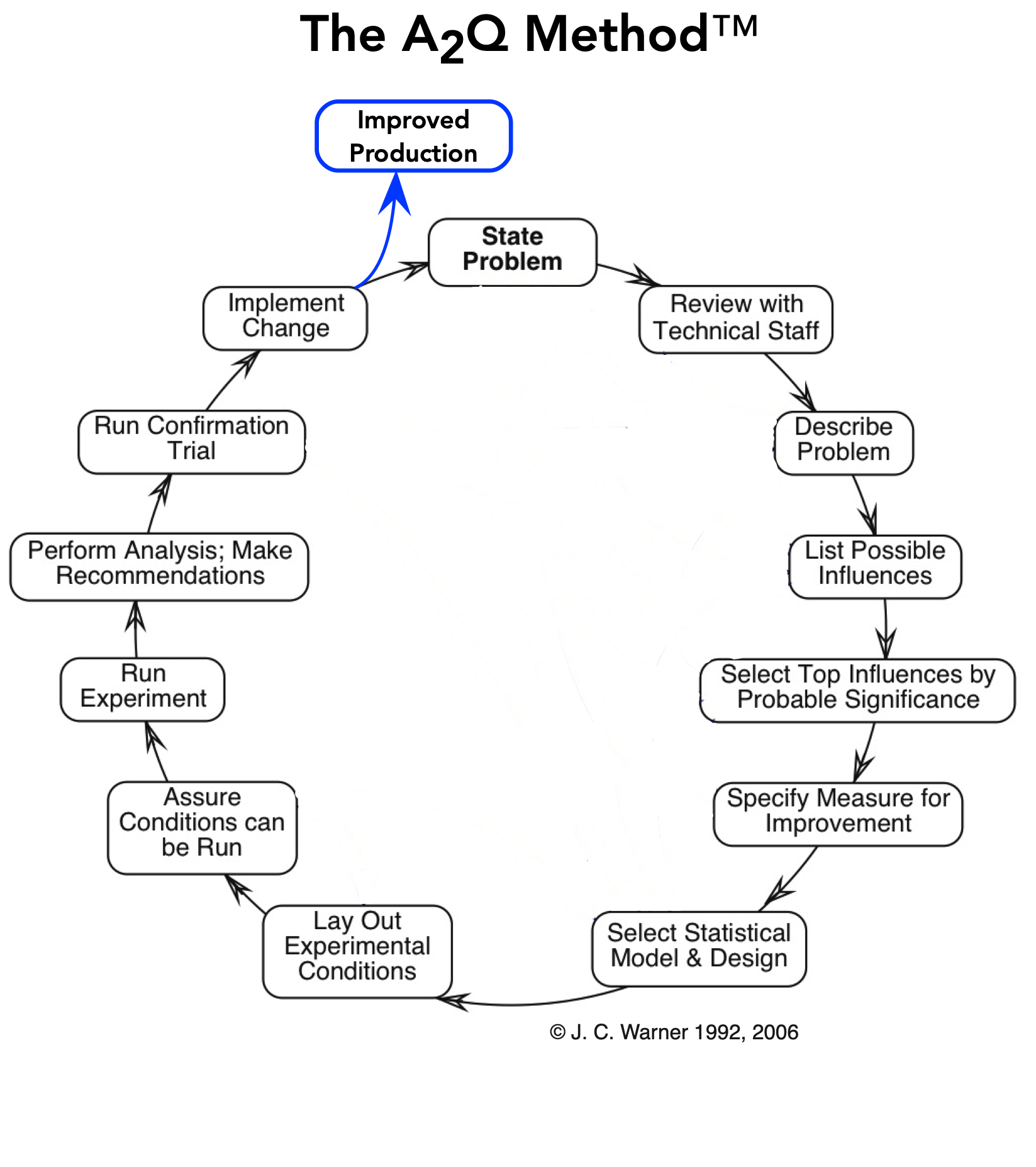

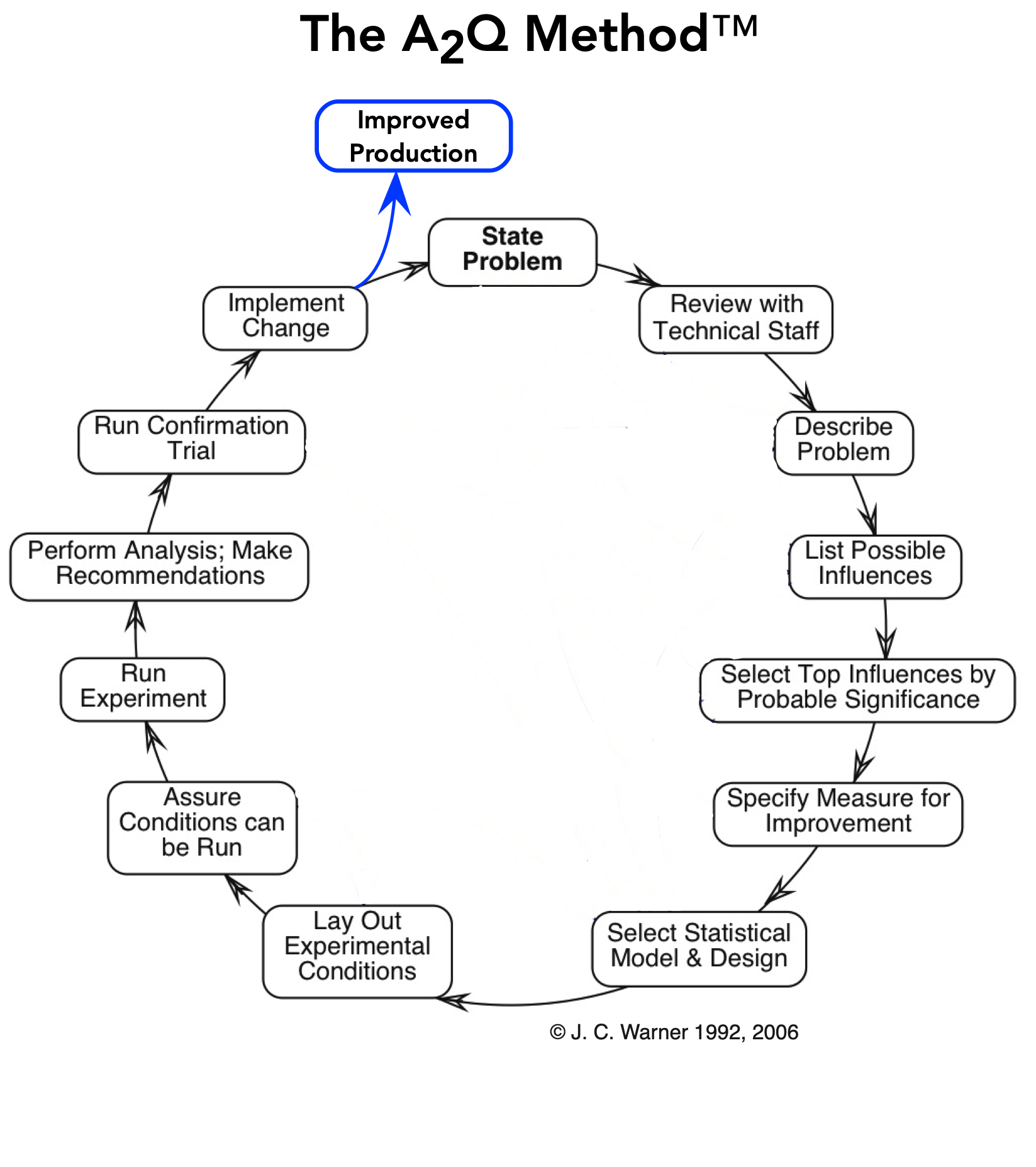

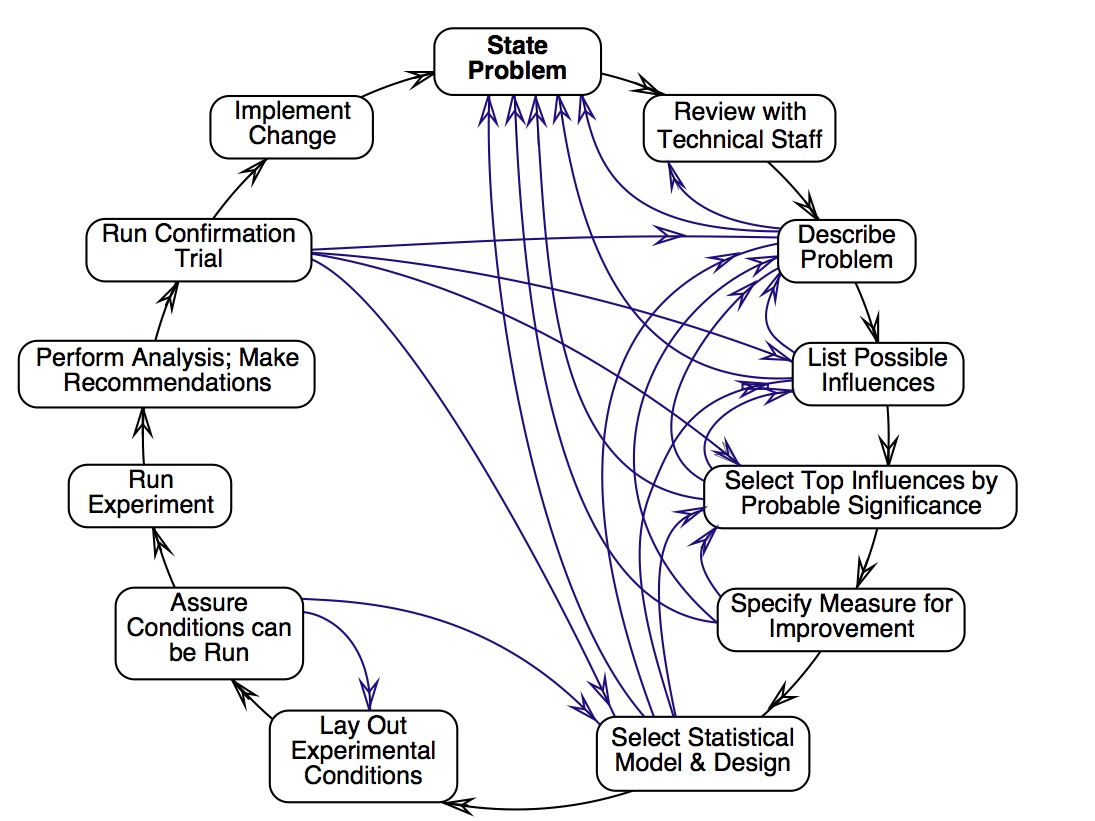

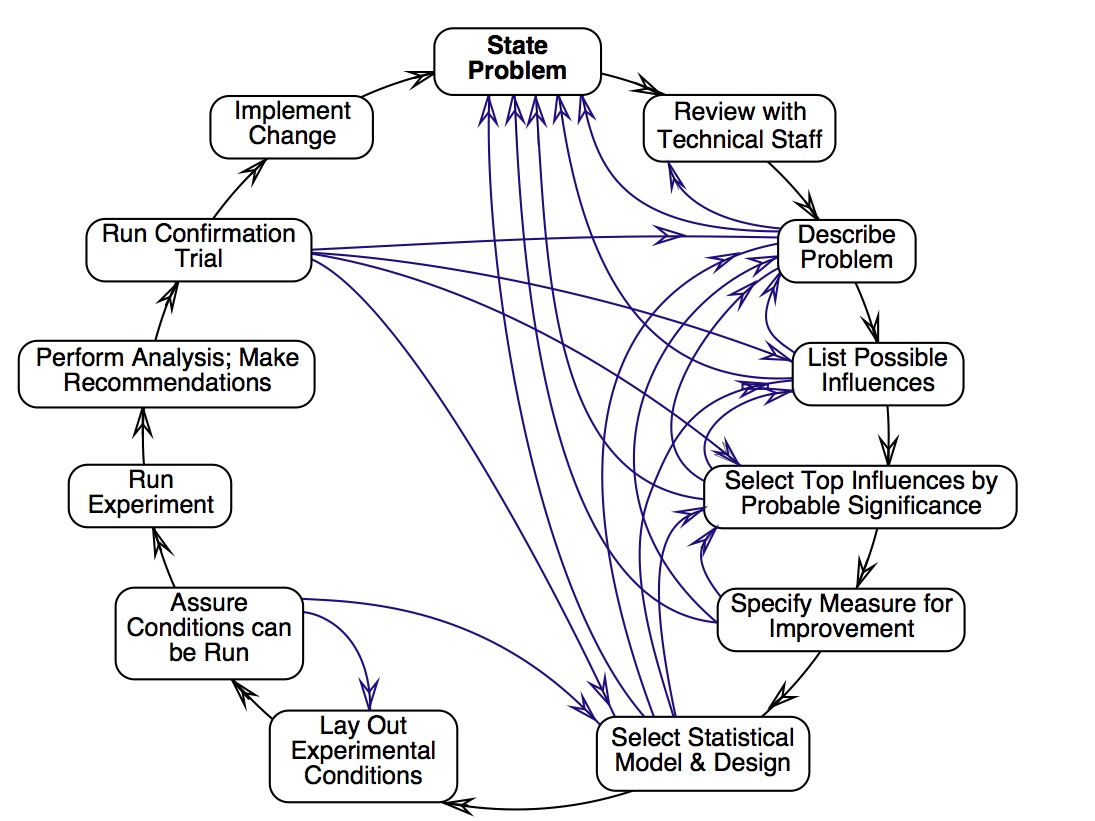

The A2Q Method is straightforward

Scientific Method writ large --

Deming's PDCA -- Plan Do Check Act explained --

With Experimental Design included!

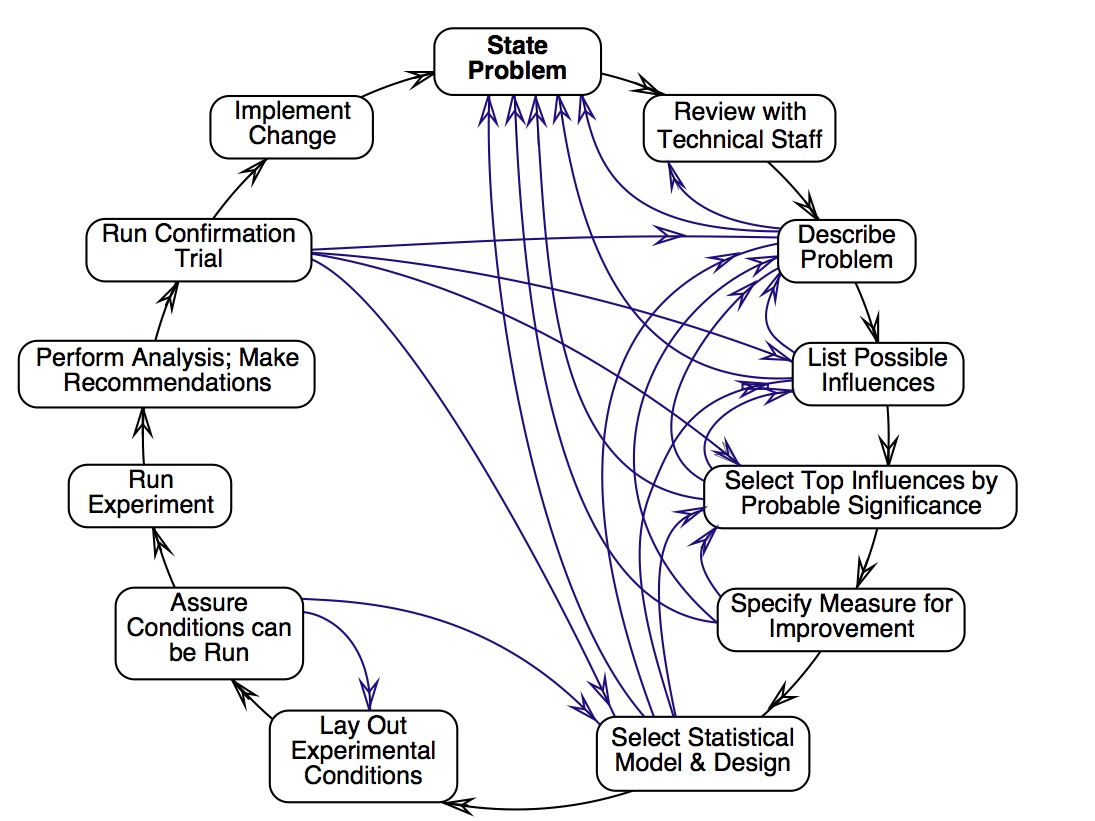

As the tech staff describes the problem & possible causes (influences), they think of more aspects -- they may change the root cause of the problem. That's all OK. Loop back (blue line) and get it down for all to see.

List at least 16 influences. Rank them all -- vote if you have to. Then pick off the top 3, 4, or 5 to study. Three is easier to understand and less complicated in the shop. Don't take the most difficult route the first time, OK?